Vibration Sensor

Vibration sensors play a crucial role in monitoring and detecting mechanical vibrations in various industrial, automotive, and IoT applications. These sensors help in predictive maintenance, structural health monitoring, and machine diagnostics by providing real-time data on vibrations and anomalies.

Experts at Razintel have dedicated their efforts to developing advanced vibration sensors, achieving high precision and reliability in detecting mechanical vibrations. With the increasing demand for smart monitoring systems, these sensors have evolved to offer high sensitivity, low power consumption, and wireless connectivity. They can detect frequency, amplitude, and acceleration of vibrations, making them essential for preventing equipment failures and ensuring operational efficiency.

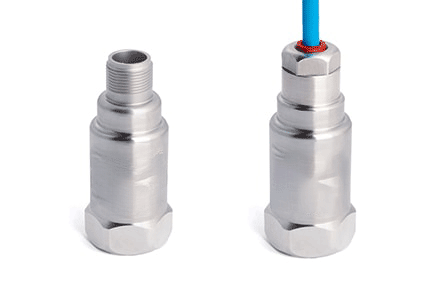

Razintel's Vibration Sensor

Razintel’s vibration sensor is an advanced, locally developed electronic device designed to monitor mechanical vibrations in real time. Engineered for industrial and IoT applications, this sensor detects vibration frequency, amplitude, and acceleration, providing critical data for predictive maintenance and structural health monitoring. By continuously analyzing vibration patterns, it helps prevent equipment failures, optimize machine performance, and enhance safety. The sensor seamlessly integrates with monitoring systems, wirelessly transmitting data for immediate analysis and alerts.

Vibration sensors come in various types, including piezoelectric, MEMS-based, and capacitive sensors. Razintel’s model utilizes MEMS (Micro-Electro-Mechanical Systems) technology, ensuring high sensitivity, low power consumption, and compact design. This makes it ideal for use in industrial machinery, smart infrastructure, and IoT-based applications.

Beyond individual installations, Razintel offers an advanced analytics platform for centralized monitoring. This system enables organizations to track vibration data across multiple machines, receive real-time alerts for abnormal activity, and optimize maintenance schedules. By leveraging this technology, businesses can extend equipment lifespan, minimize downtime, and improve overall operational efficiency.

KEY FEATURES INCLUDE

High sensitivity and accuracy

Real-time data transmission

Low power consumption

Compact and durable design

Multi-parameter monitoring

Seamless integration and analytics

FAQ

1- What is a vibration sensor?

A vibration sensor detects mechanical vibrations and provides real-time data on frequency, amplitude, and acceleration, which helps in monitoring machinery, structures, and other systems for faults and wear.

2- How does Razintel's vibration sensor work?

Razintel’s vibration sensor uses MEMS technology to measure vibrations and wirelessly transmits the data to a central monitoring system for analysis and alerts, ensuring timely maintenance and fault prevention.

3- What industries can benefit from vibration sensors?

Vibration sensors are used across various industries, including manufacturing, automotive, construction, oil and gas, and IoT, to monitor machinery, infrastructure, and devices for efficient operation and early fault detection.

4- What makes Razintel’s vibration sensor different from other sensors?

Razintel’s vibration sensor stands out due to its high sensitivity, low power consumption, compact design, and seamless integration with industrial monitoring systems and Razintel’s analytics platform.

5- What type of maintenance is required for the vibration sensor?

Regular checks for calibration and battery replacement are recommended to ensure optimal performance. Additionally, sensors should be recalibrated if moved to a different machine or system.

6- Can anyone use the vibration sensor for remote monitoring?

Yes, Razintel’s vibration sensor supports wireless transmission, allowing for remote monitoring via a centralized analytics platform, making it easy to track vibration data from multiple locations.

7- What is the lifespan of Razintel’s vibration sensor?

The lifespan of the sensor depends on factors such as environmental conditions, usage, and battery life. Regular maintenance and timely battery replacements can significantly extend its lifespan.

8- How accurate is Razintel's vibration sensor?

Razintel’s vibration sensor is highly accurate, utilizing MEMS technology to detect even minute vibrations and providing precise measurements for reliable data analysis.

9- Can Razintel’s vibration sensor be used in outdoor environments?

Yes, the sensor is designed with a durable and rugged casing to withstand harsh outdoor conditions, making it suitable for use in construction sites, oil rigs, and other challenging environments.

10- What kind of data could be expected from the vibration sensor?

The vibration sensor provides data on vibration frequency, amplitude, and acceleration, allowing you to monitor the health of machines, detect anomalies, and predict potential failures before they occur.