How Vibration Sensors Work?

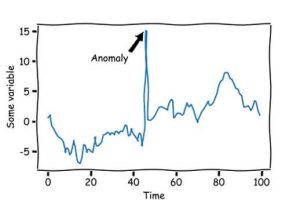

Vibration sensors are essential devices used to detect and measure vibrations in various systems and machinery. They work by converting mechanical motion into electrical signals, which can then be analyzed to determine the magnitude, frequency, and characteristics of the vibrations. This conversion is achieved through the use of specialized sensing elements, such as piezoelectric materials, which generate an electrical charge when subjected to mechanical stress, or accelerometers, which measure changes in acceleration. These sensors are crucial in applications where monitoring vibrations is necessary for maintenance, quality control, and safety, including industrial equipment, automotive systems, and even medical devices. By analyzing vibration patterns, they can help identify potential issues such as imbalances, misalignments, or wear and tear, preventing costly breakdowns and ensuring the smooth operation of machinery.

Understanding Vibration in Industrial Equipment

Vibration in industrial equipment can be a normal part of operation, but in some cases, it may indicate underlying mechanical issues. In machine monitoring, vibrations are generally classified into two types:

1. Axial (Thrust) Vibration

Axial vibration refers to longitudinal shaft movement that occurs parallel to the motor shaft. This type of vibration is often caused by shaft misalignment, leading to excessive movement along the axis of rotation.

2. Radial Vibration

Radial vibration occurs when a force is exerted outward from the shaft, perpendicular to its axis. One common cause of radial vibration is an imbalance in rotating components, such as a heavy spot in the motor. For example, a deformed fan blade can create an uneven distribution of mass, pulling outward on the shaft as the fan spins, resulting in increased radial vibration.

Monitoring and analyzing these vibration types can help identify mechanical issues early, preventing equipment failure and ensuring optimal performance.

Types of Vibration Sensors

Piezoelectric Accelerometers – Utilize the piezoelectric effect, where mechanical stress from vibrations generates an electrical charge. These sensors are widely used due to their high sensitivity and reliability. When mechanical force is applied to a piezoelectric material, it generates a voltage proportional to the vibration.

MEMS-Based Accelerometers – Microelectromechanical systems (MEMS) accelerometers offer advantages such as compact size, low cost, and integration into digital systems. A small mass attached to a cantilever beam moves in response to vibrations, with the movement being converted into an electrical signal.

Velocity Sensors – Measure the rate of change of displacement, commonly used in rotating and reciprocating machinery for predictive maintenance. It measures the rate of displacement change, providing a vibration velocity output.

Proximity Sensors – Monitor the relative motion between a rotor and stator without physical contact, typically using magnetic or capacitive principles. It uses magnetic fields or capacitance to measure relative motion between two objects without physical contact.

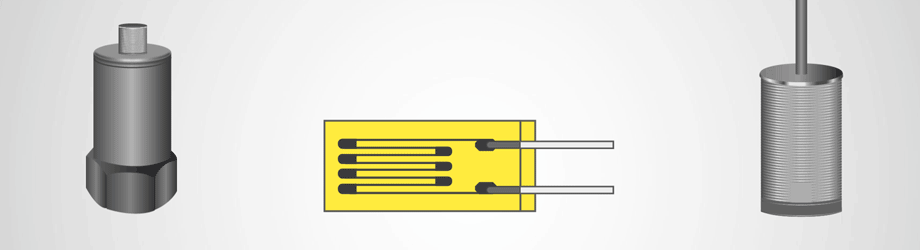

Accelerometer

Strain Gauge

Eddy-Current

Types of Vibration Sensors

Now that we understand what vibration is, let’s explore the different types of sensors used to monitor it.

1. Accelerometers

Accelerometers measure vibration or the acceleration of motion in a structure. These sensors contain a transducer that converts mechanical force caused by vibration or motion changes into an electrical signal using the piezoelectric effect.

There are two main types of piezoelectric accelerometers:

1.1 High Impedance Accelerometers

High impedance accelerometers generate an electrical charge that is directly connected to measurement instruments. Due to their sensitivity and specialized requirements, they are commonly used in research facilities or high-temperature applications.

1.2 Low Impedance Accelerometers

Low impedance accelerometers feature a built-in micro-circuit and transistor that converts the generated charge into a low-impedance voltage. This design allows for easier integration with standard instrumentation, making them widely used in industrial applications.

2. Strain Gauge Sensors

Strain gauge sensors measure the strain on machine components. They function by detecting variations in electrical resistance as force, pressure, tension, or weight is applied.

When an external force is exerted on a stationary object, stress and strain occur. Applying strain to a metallic wire causes its length to increase and diameter to decrease, resulting in a change in resistance. This resistance variation is then measured to determine the strain on the machine component.

3. Eddy-Current Sensors

Eddy-current sensors, also known as capacitive displacement sensors, are non-contact devices that measure the position or displacement of a conductive component. These sensors operate using magnetic fields and consist of a probe that generates an alternating current at its tip.

This alternating current induces small circulating currents, called eddy currents, in the monitored component. The sensor detects changes in the interaction between the probe’s magnetic field and the eddy currents, producing a voltage proportional to these variations.

For optimal operation, the monitored component should be at least three times larger than the sensor’s diameter; otherwise, advanced calibration may be required.

Each of these vibration sensor types serves specific applications, helping industries monitor equipment health, detect potential failures, and ensure smooth operation.

Understanding Vibration Sensors: Functionality and Applications

Vibration sensors play a crucial role in monitoring and analyzing mechanical motion across various industries. Here’s a detailed breakdown of their components, types, working principles, and applications.

1. Sensing Element

At the core of every vibration sensor is a sensing element that detects mechanical vibrations and converts them into an electrical signal for further analysis.

2. Conversion to Electrical Signal

The sensing element transforms mechanical vibrations into electrical signals, enabling precise measurement and monitoring.

3. Applications of Vibration Sensors

Machine Condition Monitoring – Detects early signs of mechanical failure, preventing costly downtime.

Industrial Automation – Ensures smooth and efficient equipment operation by monitoring vibration levels.

Security Systems – Detects unauthorized access by sensing unusual vibrations.

Home Automation – Triggers actions such as turning on lights or sending alerts based on detected vibrations.

By leveraging different sensing technologies, vibration sensors help industries optimize performance, enhance safety, and extend the lifespan of critical equipment.